The Increasing Use of 3D Printing in Hotel Furniture Manufacturing and Design

The Increasing Use of 3D Printing in Hotel Furniture Manufacturing and Design

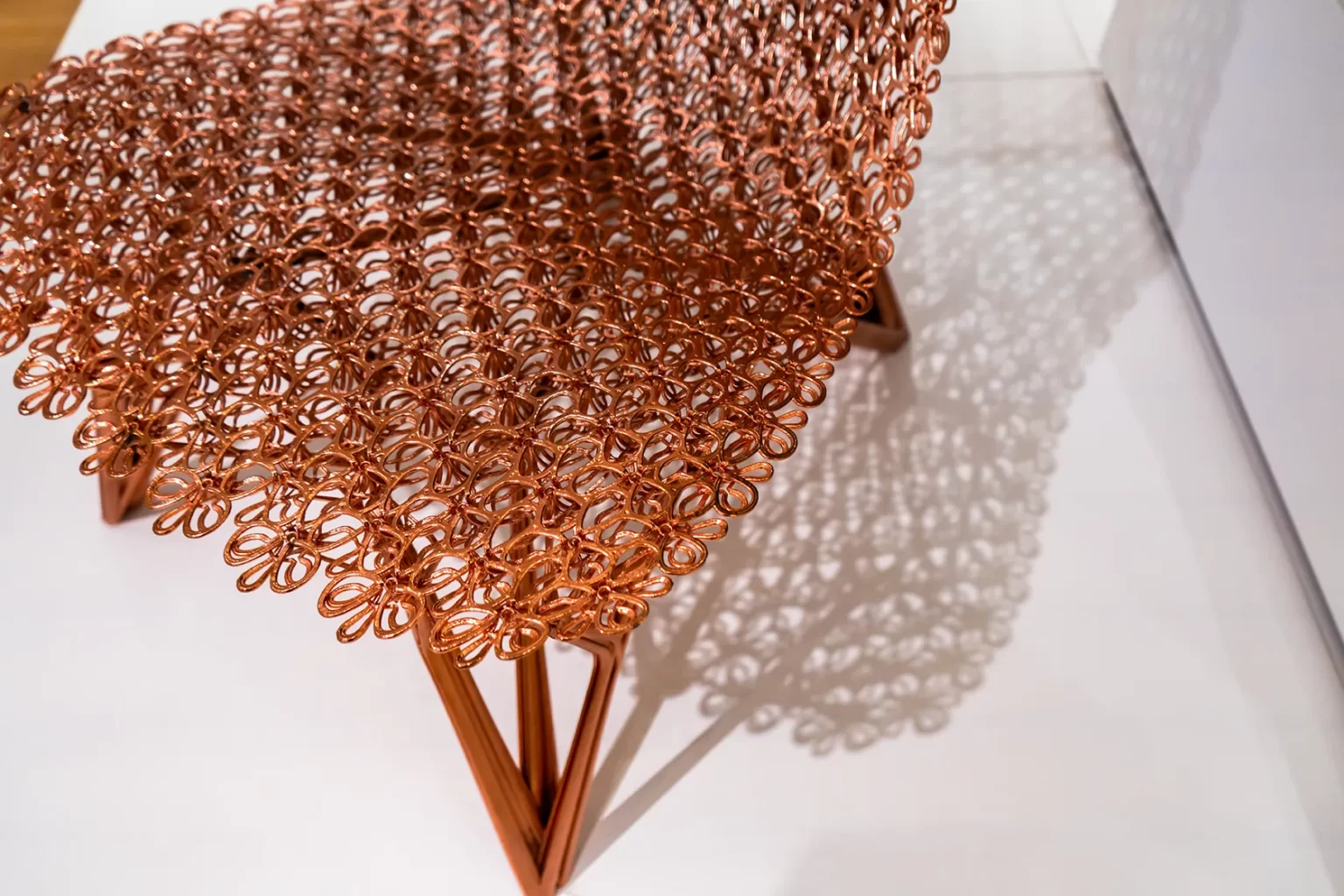

3D printing is a revolutionary technology opening creative possibilities in hotel furniture manufacturing and design. This cutting-edge technology can bring complex geometries to life.

This digital craftsmanship has already produced chairs, lamps, decorative hardware, and tables. Here are five ways 3D printing can be used in hotel furniture manufacturing and design.

Quickly Test Multiple Prototypes

A 3D printer removes one traditional barrier in the design process: testing prototypes. To realize a traditional design requires multiple repeated processes, including prototype design, mold making, testing, and re-improving the prototype design. It requires a manufacturer with the right team, equipment, and expertise.

Instead, a 3D printer can produce a lightweight prototype relatively quickly and inexpensively. Designers can create iterations of a design and test it. Designers are using 3D printers to bring new and complex geometries to life, enjoying the freedom to experiment with forms and styles.

Develop Customized Pieces With Precision

Some customers will always prefer classic furniture designed with wood and materials not available through a 3D printing process. Still, customers who appreciate the modern style created by 3D printing will be able to access customized pieces at a lower price point.

Just as creating a prototype is more straightforward, a customized version of a design can be printed without adding cost to the process.

Complex Furniture Molding

As designers experiment with 3D printing technology, some produce irregularly shaped furniture and intricate designs that would be difficult or impossible to build using traditional molds. Since 3D-printed furniture is created in layers based on a digital design, it is free of the limitations of mold-making.

Interestingly, 3D printing can also revolutionize how furniture molds are created. Using materials such as plastic, ceramic, recycled paper, or metal, molds can be printed directly from a computer-generated model. If the mold needs to be adjusted, it can be done more efficiently than using traditional mold-making means.

This allows for more complex molds to be created with multiple adjustments available during the design process.

Add New Sustainable Options to the Manufacturing Process

3D printing expands hotel furniture manufacturing’s options for sustainable production. The process can use upcycled materials. Furniture parts can more easily and cost-effectively be produced on demand in small quantities, reducing waste.

Digital files can be created anywhere and then printed locally, potentially reducing the carbon emissions associated with long-haul shipping and transport.

A notable way 3D printing technology can potentially increase the sustainability of hotel furniture manufacturing is by reducing repeatability in the product development process. Specifically, using 3D printing technology to pretest and rework furniture prototypes before they see a traditional production process. This phase can be both faster and more concentrated using this technology.

Printing molds can also reduce overall production time. Since that process would be taken in-house instead of outsourced, it simplifies internal, team communication and product flow.

Stunning and Creative Use and Reuse of Materials

The 3D printing process opens the door to the reuse of a variety of materials that would otherwise be discarded to create stunning and unique designs. One noteworthy example: furniture has been printed out of melted-down discarded refrigerators. However, not all of the materials used in 3D printing are environmentally friendly or upcycled.

Plastic is the material most people associate with 3D printing. Plastics for printing can be sourced from biodegradable products like corn starch and sugar cane. Various plastics that are not biodegradable are also used, some broken down from discarded plastic and some new.

Other materials that can be 3D printed include:

- Filaments of 30 to 40% wood fiber and 60 to 70% polymer (to create wood materials)

- Nylon powder

- Alumide powder (a mix of polyamide and gray aluminum)

- Metal dust, including stainless steel, bronze, gold, nickel, aluminum, titanium,

- Resins

- Carbon fiber

- Graphene

- Graphite

- Paper (mixed with glue)

While not all of these are suitable or cost-effective for hotel furniture manufacturing, the list of materials that can be used for 3D printing continues to expand.

Exciting Technologies Are Emerging

3D printing is one of the exciting emerging technologies that can add to hotel furniture manufacturers’ capabilities while streamlining operations and increasing sustainability. It opens the door to striking and creative new modern furniture designs.

At Mittman, we stay on top of emerging technology. Our more than 60 years of success building hospitality furniture of distinctive quality demonstrates our willingness to grow and evolve with the industry. Connect with our team today to discover how we can build your hospitality furniture design with a competitive edge in value, scale, and capacity.